Milling

Technology and expertise: a perfect match

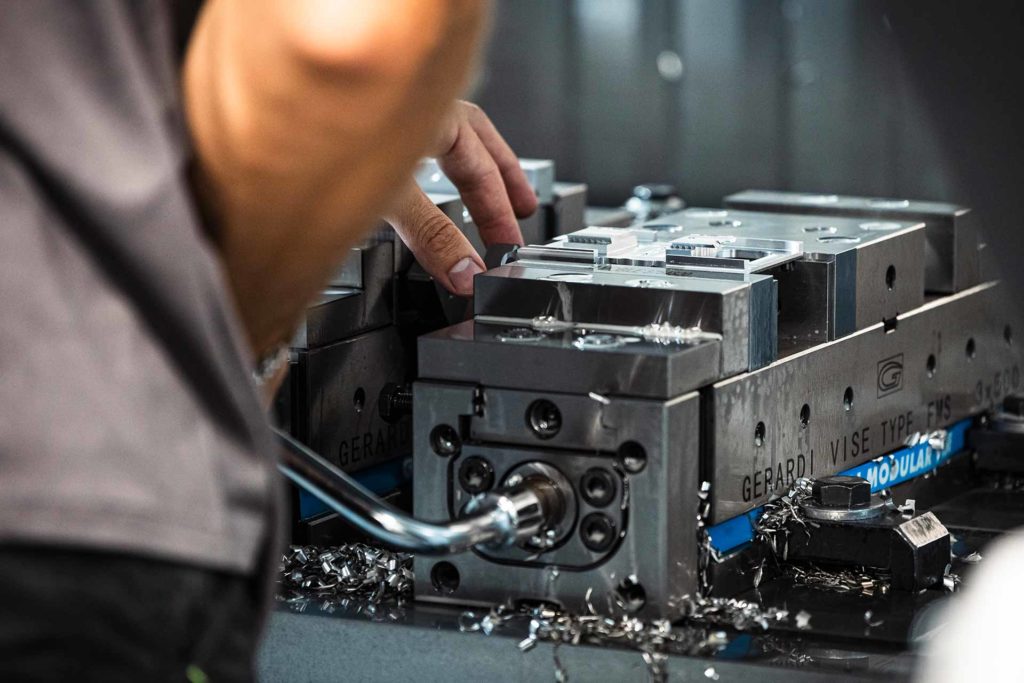

The G.B.G. milling department is able to operate with efficiency and speed, crucial factors in the processing of pieces with extremely precise dimensions and finishes.

The range of materials used depends on the specifications of the project requested by the customer, in general the metal alloys processed are steel, aluminium and Grade 5 titanium.

The company has a cutting-edge machinery park, which consists of 33 numerically controlled milling machines. Depending on the position of the spindle, the machinery in the milling department is divided into two types.

Horizontal Machine Models

- MCM MP10 multi-pallet type (10 pallets) with supervisor

- MCM MP9 multi-pallet type (9 pallets) with supervisor

- Mandelli Thunder 500 multi-pallet (2 pallets) with supervisor

Vertical Machine Models

The instruments belonging to this category can be divided into various subgroups.

Short bench (2000 mm):

- Rema Control Galileo

- Chiron Fz08W

- RIVA RS80

Long bench (3000 mm):

- PFG VMC 3000

- Rema Control Newton

- Vitech VMC2500

5 AXES:

- Vitech VMC2500

Saws by material:

- FORTE S361 band saw for cuts up to 360*360 mm

- CONNI S380 disc saw for cuts up to Ø 100 mm

- Pedrazzoli Brown 300 Cutting Saw

Laser numbering machine:

- Laser Automator Superior numbering machine for markings up to 180*180 mm