-

Mechanical industry

Leader in the precision mechanics since 1969

Leader in the precision mechanics since 1969

-

Quality and innovation

Constant commitment and research to guarantee quality and innovation.

Constant commitment and research to guarantee quality and innovation.

-

Strategy at your service

A trusted strategic partner

A trusted strategic partner

-

Maximum precision

Workmanship tailored to perfectionWorkmanship tailored to perfection

Precision mechanical machining

Tailor-made solutions since 1969

The metalworking company G.B.G. specialises in precision machining based on customers’ drawings and projects. Since 1969 it has offered concrete and original tailor-made solutions at high quality standards to satisfy all Customer needs.

- Advanced processing technologies

- Sustainability

- Employee well-being

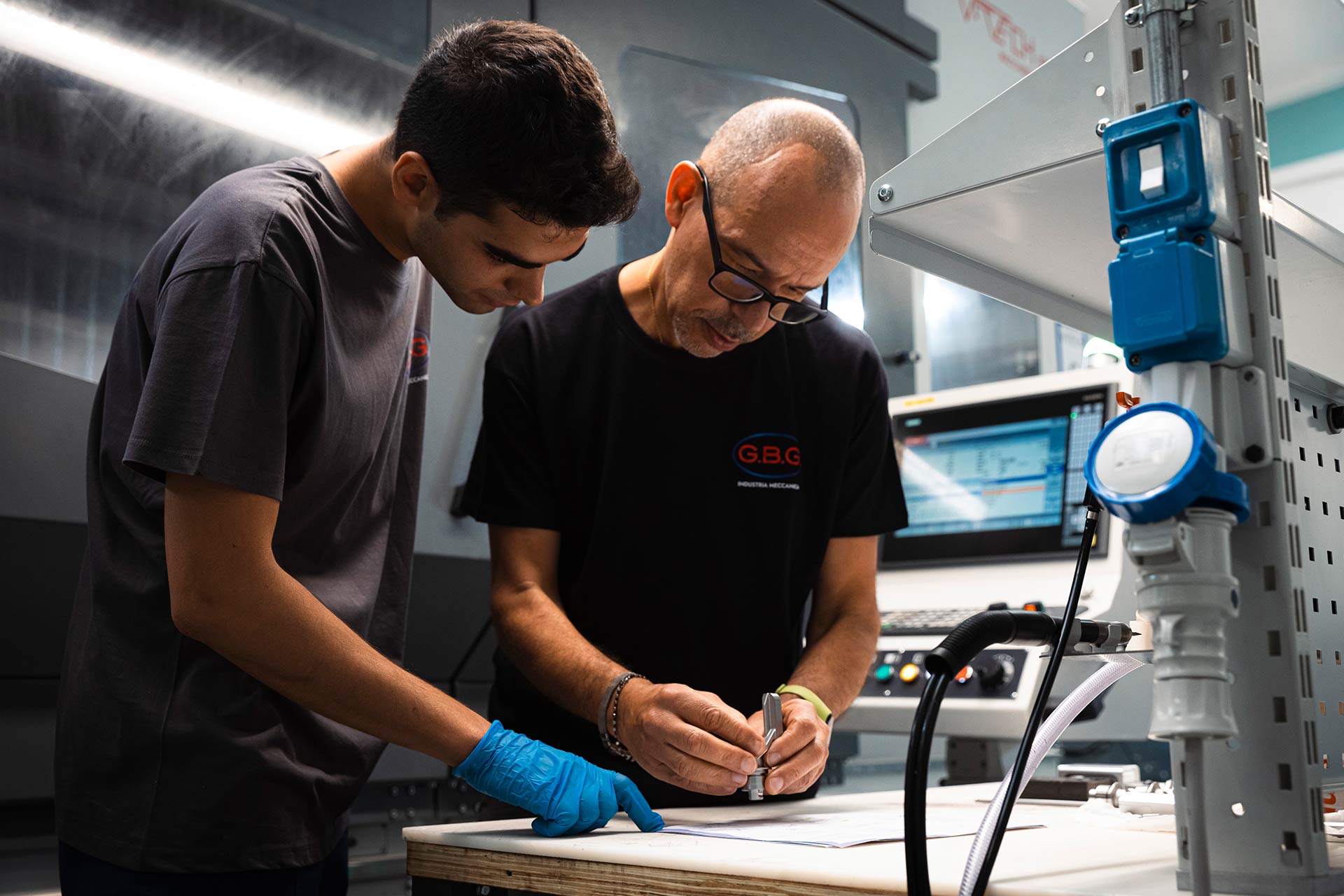

- Continuous training

- Guaranteed quality

- Tailor-made solutions

- Respect for deadlines

- Maximum precision

- Reliability and resistance

G.B.G. Mechanical industry

Guarantee of quality and safety in multiple industrial sectors

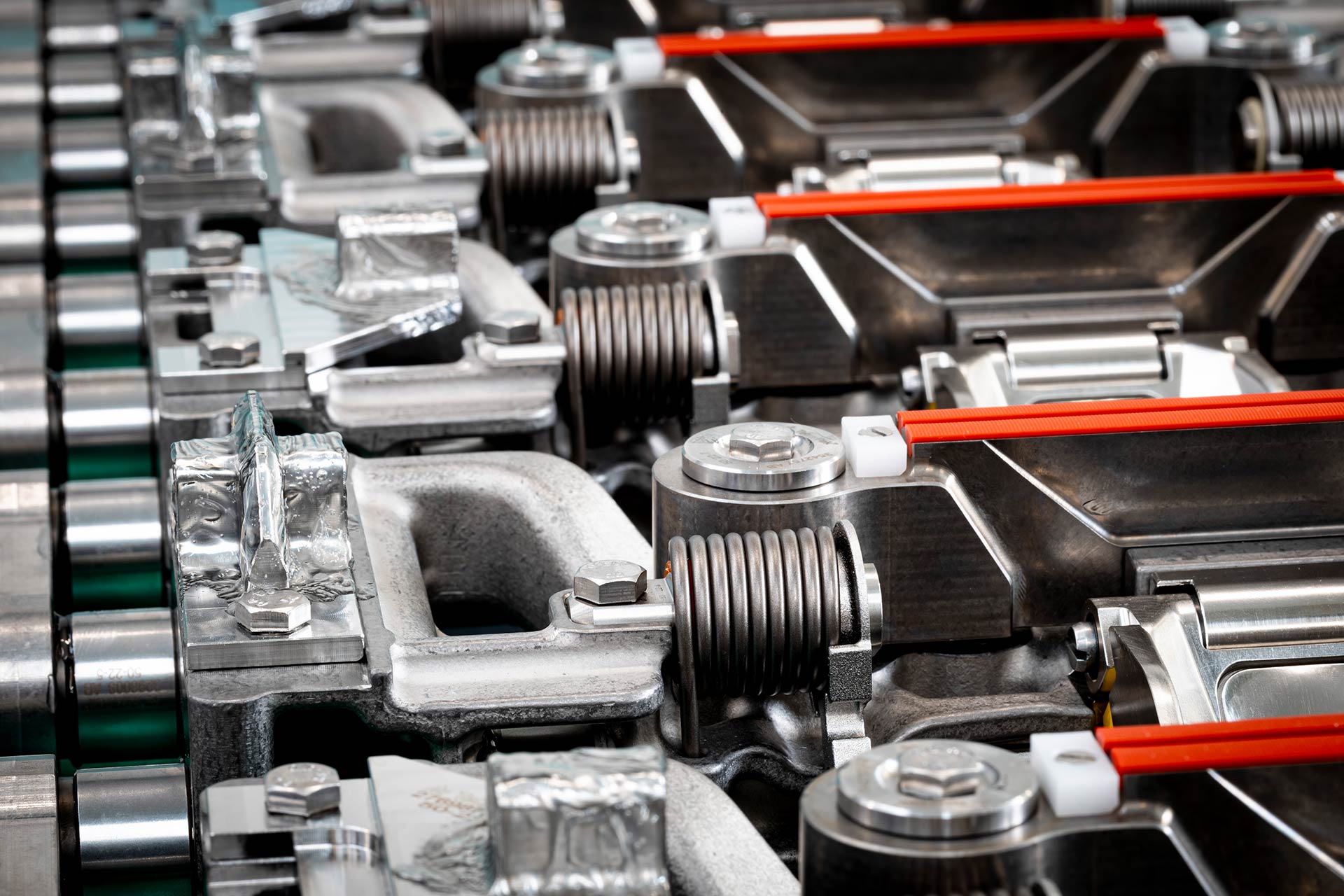

The workshop creates customised precision mechanical components using a cutting-edge fleet of machines, which allows it to work with materials such as titanium, stainless steel and aluminium alloys.

Versatility and technical efficiency have allowed G.B.G. to become a point of reference in various precision engineering industries. The company operates in the food plant engineering, industrial automation and energy sectors.

Quality and constant investments in always efficient company policies are the pillars on which we build an impeccable service, even for the most demanding customer: an approach of this type allows us to increase the competitiveness of the product on the market and guarantees customers access to the most advanced mechanical solutions.

An impeccable working environment is the key to excellence. Order, cleanliness and organisation are real dogmas on which commitment and protection towards the staff are based. The constant attention to the professional and physical well-being of the worker materialises above all in periodic checks to assess risks and investments in devices for correct environmental air conditioning.

Quality assurance

Safety

Constant innovation

Innovation and sustainability

2030 Agenda

G.B.G. promotes sustainable development strategies by operating in compliance with the 2030 Agenda.

The company has important optimisation projects underway for resource management, the implementation of which is certified by the Sustainability Report.

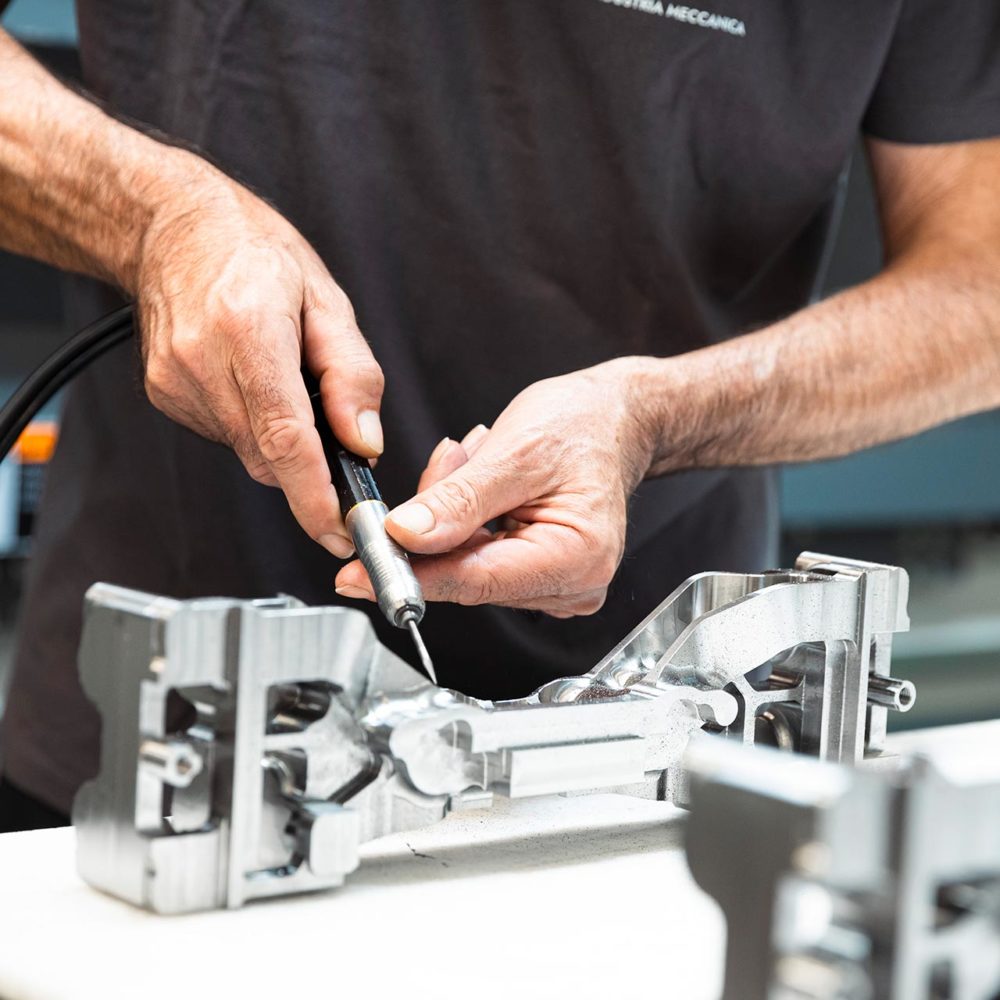

Prototyping

Upon customer request, G.B.G. offers a prototyping service for customised mechanical solutions.

Milling

G.B.G. has a cutting-edge machinery fleet, capable of processing a vast range of materials with efficiency and speed.

Metrology room

To guarantee the quality of the products manufactured, G.B.G. uses ACCREDIA certified measuring instruments managed by highly qualified technicians.

Sanding and cleaning

In the tumbling department, the pieces are smoothed and polished using a special water recirculation system.

Testing

G.B.G. relies on Zeiss international excellence in order to carry out dimensional checks compliant with repeatability standards.

The story continues

The shareholders guiding the company

Ciriaco Brogna

Founding shareholder

Maurizio Brogna

Second generation shareholder

Mirko Grandi

Second generation shareholder

Giorgio Grandi

Second generation shareholder

Paolo Valentini

Second generation shareholder

Renzo Grandi

Founding shareholder

G.B.G. S.r.l.

- Via Campania 3 - 41051, Montale Rangone (MO) ITALY